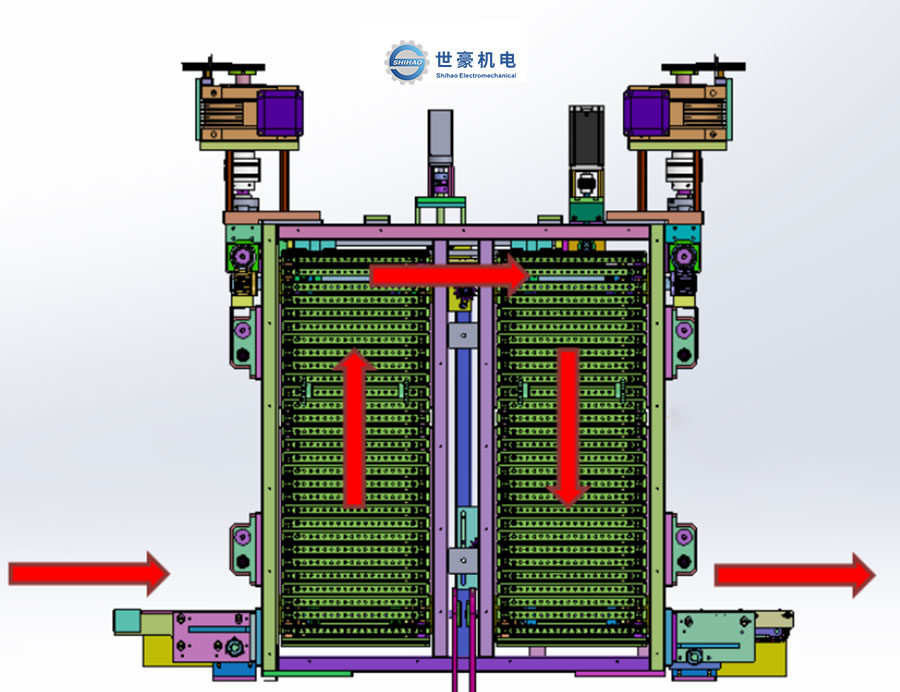

垂直固化炉

物料在炉腔内垂直方向运行,充分利用空间高度,有效减少设备占地面积

立式多层结构、带前后接驳台;

高效热风循环、精准控温、充氮气(厌氧)烘烤;

智能化控制、数据采集上传等,支持按需定制;

革新热固化工艺:智能垂直固化炉,为PCB、半导体、光伏制造赋能

“生产线空间紧张,扩产难?传统卧式炉能耗高,固化不均匀影响良率?工艺数据难以追溯,品控压力大?”

世豪智能垂直固化炉,革命性的立式设计,将生产向“高度”要空间,占地面积比传统设备减少50%-70%。结合智能化控制系统,为您打造一个节省空间、节能减排、提升良率与可追溯性的高效热固化解决方案。

垂直固化炉 vs. 传统回流焊炉

| 对比维度 | 传统回流焊 | 垂直固化炉 | 垂直固化炉优势 |

| 工作原理 | 主要针对SMT焊接,通过预设温区进行快速加热冷却 | 专为热固化/烘烤设计,强调恒温均匀性和时间控制,可充氮创造厌氧环境 | 工艺专用:更适合胶水固化、油墨烘干、材料退火等需要长时间恒温的工艺 |

| 结构布局 | 水平隧道式,流程长,占地面积大 | 垂直多层循环,物料在腔体内垂直运动,充分利用厂房高度 | 节省空间:极大减少平面占用,优化车间布局,支持产线密集化 |

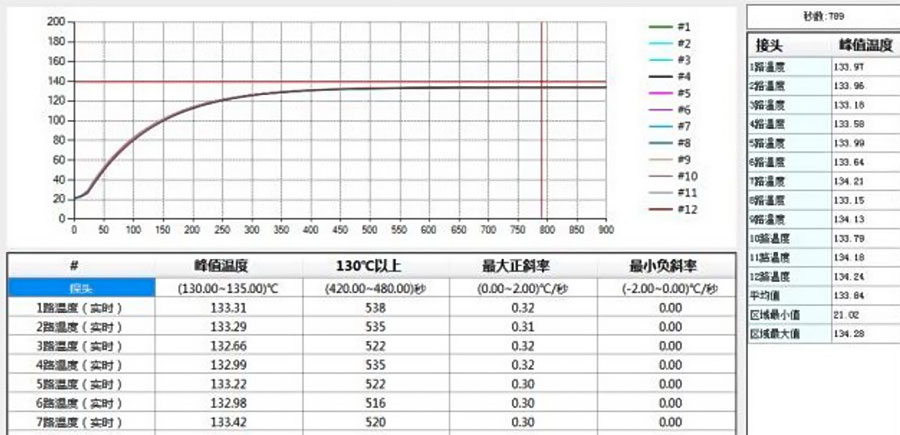

| 热场均匀性 | 温区多,但横向温差可能存在 | 立体高效热风循环系统,配合独特风道设计,确保腔体内各层、各点温差≤±1.5℃ | 提升一致性:消除固化不均导致的色差、性能不一等问题,显著提高产品良率 |

| 气体环境 | 通常为空气环境,少数可充氮 | 标准配置充氮系统,可快速建立低氧环境(氧含量<100ppm),防止氧化 | 满足高端工艺:完美应对IC封装、高端PCB等厌氧烘烤要求 |

| 能耗表现 | 连续工作,炉体散热面积大,能耗高 | 模块化加热、优异保温层、热风内循环,比同产能卧式炉节能30%以上 | 降低运营成本:长期使用,电费与氮气消耗大幅节约 |

| 智能化程度 | 基础PLC控制,数据记录有限 | 智能触摸屏+物联网模块,实现配方管理、远程监控、MES数据上传,完整追溯生产过程 | 数字化管理:满足工业4.0要求,为品质分析和工艺优化提供数据基石 |

行业应用

PCB制造业:阻焊油墨固化、字符烘烤、软板PI固化、高频板材热处理。改善工艺中的均匀性(避免黄变、气泡)、充氮(防止铜箔氧化)、洁净度(无尘设计)等问题。

半导体封装:环氧塑封料(EMC)固化、芯片粘贴胶固化、Underfill底部填充胶固化。极致的温控精度(±1℃)、超低氧环境(<50ppm可选)、防污染(不锈钢腔体、FFU过滤)。

光伏电池生产:PERC电池背钝化(Al2O3)固化、浆料烘干、薄膜烧结。高产能匹配、快速升温能力、适用于大尺寸硅片(如182/210mm)的载具定制。

精密涂覆与胶粘剂固化:手机中框/背板胶水固化、光学镜头粘合固化、医用器件组装固化。程序控温(多段升温斜率控制)、洁净环境、小批量多品种的柔性化生产。

“您的工艺是否需要更高效、更智能的热固化解决方案?立即联系我们,获取专属行业方案与免费试样机会!”

在线咨询、电话热线、获取方案、免费现场勘测

| 设备尺寸 | 7200*3000*2500mm |

| 罐体直径 | Φ1000mm |

| 压力范围 | 0.1~0.8Mpa |

| 作业时间 | 可在参数页面设置,1~999min |

| 升温速度 | 室温至100°C,升温时间15min |

| 温度控制精度 | ±1℃ |

| 均温性 | 升温时士5℃℃,恒温时士3°C |

| 可存储配方数量 | 100组 |

| 温度设定范围 | 室温~100°C |

| 托盘尺寸 | 最大980*1180mm,采用双层托盘布局 |

| 数据上传 | 可配备手持式读码器,人工扫描产品ID,并上传至SFC/MES |

| 电源/功率 | AC380V/50HZ,20KW |