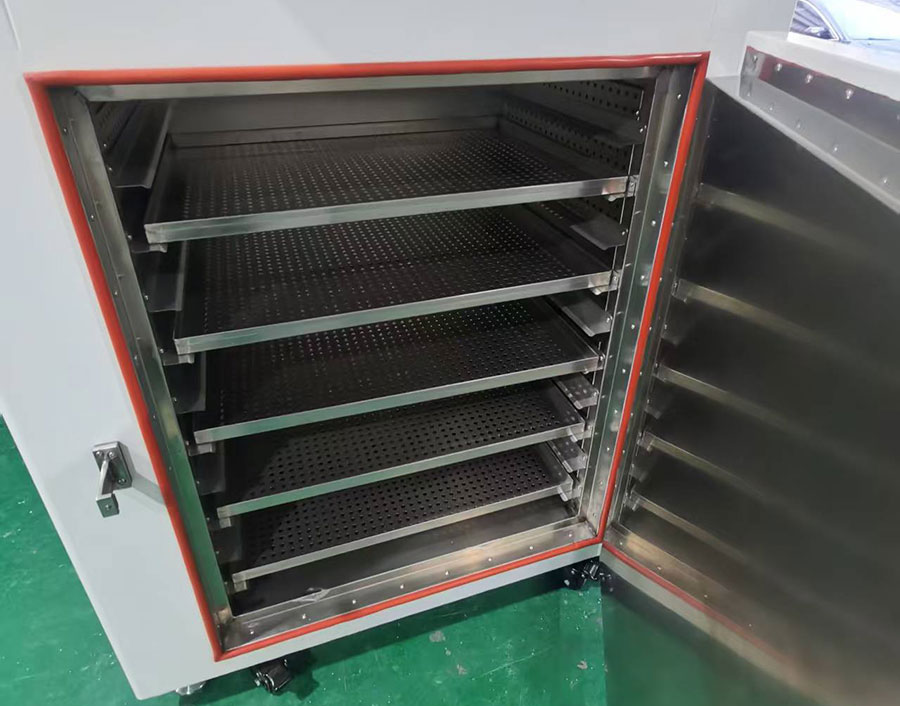

双炉腔烤箱(充氮选配)

两个独立工作的腔体;

高效热风循环,精准控温;

字母料车上下料(限左右排列腔体);

可选配充氮功能和过滤器(百级无尘);

智能化控制,支持数据采集上传等功能,可按需定制

Dual Chamber Manual Curing Oven for R&D and Small Batch Production

世豪双炉腔烤箱是一款专为高端制造业设计的精密烘烤与固化设备,采用双独立工作腔体设计,支持同步或异步生产模式。设备集成了高效热风循环系统、精准温控技术,并可选配充氮保护功能和百级无尘过滤系统,满足电子制造领域对烘烤工艺的严苛要求。

产品优势

1. 双腔体独立生产系统

两个腔体可独立设置温度、时间等参数,支持不同温度曲线与时间周期的同步操作。此设计将处理吞吐量提升一倍,减少待机时间,提升设备利用率30%以上,可同时处理多种工艺或物料。

2. 紧凑设计,优化成本与占地面积

创新的单体双腔设计较购置两台独立烘箱节省高达40%的投资成本。紧凑的占地面积在有限的实验室或生产空间内实现最大化热处理能力,带来卓越的投资回报率。

3. 精准温控技术

每个腔室均配备独立可编程控制系统,实现±3°C温度均匀性,支持32段可编程温度曲线。配置HEPA高效过滤器,达到Class 100无尘标准,广泛适用于易受氧化和污染影响的半导体、SIP封装及先进电子产品等敏感工艺。

4.子母料车上下料系统(左右排列腔体专用)

一次装载可服务两个腔体,实现快速将物料在腔体间转移,减少作业人员50%的工作量。系统配备智能配方管理及数据记录/上传功能,确保全流程可追溯性与可重复性。其设计可无缝衔接研发原型与大规模生产,并支持未来集成至更高阶自动化系统,是实现研发原型到量产转化的完美解决方案。

应用场景

广泛应用于PCB板阻焊油墨固化、字符烘烤、板材预烘等制造流程,双腔设计可同时处理不同厚度的PCB板,充氮功能防止氧化;芯片封装、电感变压器、传感器等电子元器件制造,百级无尘环境避免污染,精准温控确保批次一致性;OLED/LCD面板烘烤、光学胶固化等面板制造流程,均匀的热场分布,避免面板受热不均产生缺陷;晶圆烘烤、封装固化、底部填充等半导体元器件制造场景;多层堆叠结构的均匀固化/系统级封装(SIP)等复杂材料的热处理需求。

| 设备尺寸 | 2600*1680*2200mm |

| 极限耐热温度 | 250℃ |

| 隔热性能 | 内腔温度200℃时,外壳温度50℃以下 |

| 升降温速度 | 室温升至200°C, 升温时间 20S |

| 温度控制精度 | ±0.1℃ Advantages |

| 均温性 | 升温时±5℃,恒温时±3℃ |

| 内腔尺寸 | (800*900*1500)mm*2 |

| 电源/功率 | AC380V/50HZ 42KW |