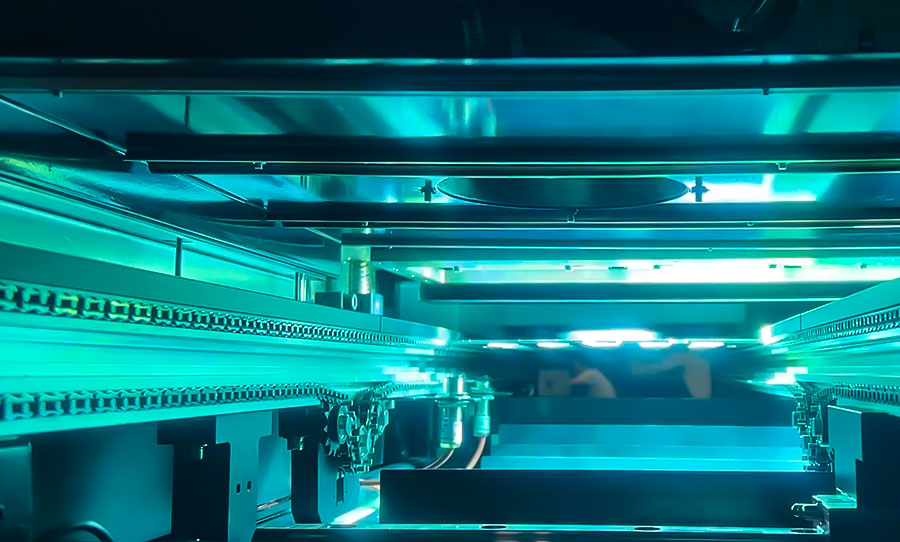

在线式无极灯UV固化炉

单/双通道可选、轨道宽度可调节;

多光源照射、自动降温;

高效节能、低温操作、环保无污染;

智能化控制,数据采集上传等可按需定制;

在线式无极灯UV固化炉|高效节能的工业固化解决方案

在线式无极灯UV固化炉采用先进的无极灯技术,通过特定波长的紫外线(UV)触发光敏材料的瞬间聚合反应,实现3-5秒快速固化。相比传统热固化方式,设备工作温度低(<50℃),节能70%以上,且无VOCs排放,完美契合现代制造业对高效率、低能耗、环保化的生产要求。

设备特色优势

1. 灵活配置设计

单/双通道可选适应不同产能需求,双通道设计产能翻倍;轨道宽度200-800mm无极调节,兼容多样化工件尺寸;

标配3-6组模块化UV灯组,照射强度500-8000mW/cm²可调。

2. 智能控制系统

7英寸触摸屏,实时显示温度、速度、UV强度等关键参数;可存储50组以上工艺配方,实现一键调用配方;标配RS485/以太网数据采集接口,支持MES系统对接。

3. 稳定运行保障

自动温控系统,内置风冷+水冷双降温系统,灯罩温度<80℃;智能保护机制,过温、过流、漏电等多重保护;无极灯寿命>10000小时,维护成本降低60%。

四大行业解决方案

1. 电子制造业|胶水瞬间固化

传统热固化耗时10-30分钟,产线节拍慢;高温可能损伤精密电子元件;溶剂型胶水容易产生有害气体等如何解决?

世豪uv固化炉,实现3秒快速固化UV胶水,生产节拍提升20倍;低温工作温度<50℃,保护敏感元器件;100%固含量UV胶,无溶剂挥发环保安全;

2. 印刷包装业|油墨即时干燥

传统印刷油墨干燥流程中,需要将印刷好的产品晾置场地,占用大量生产空间;因天气或环境原因干燥不彻底导致背面粘脏;溶剂挥发影响车间环境等问题。

世豪20年专注UV固化炉制造,实现油墨在线即时干燥,印刷后立即固化无需晾置;UV油墨100%彻底固化,彻底消除背面粘脏情况;色彩饱和度提高20%,提升品质耐磨性增强

3. 汽车制造痛点与解决方案

汽车零件喷漆后都得进大烘道,温度高、耗电大,一等就是几十分钟。特别是塑料件,像车灯、内饰板这些,一烤容易变形,良率上不去,库存还压得多。用我们的UV固化炉就省事儿多了——5秒钟照完就干,根本不用等。关键是温度低,塑料件不变形,能耗比传统烘道能省70%以上的电。像车灯密封胶、内饰板上的油漆、还有那些小标牌,现在都能快速搞定,生产节奏快多了。

4. 医疗器械痛点与解决方案

医疗器械最怕两样:不干净、不耐热。传统烘烤有热气流动,容易带进灰尘细菌,温度一高还可能把塑料材质的注射器、导管给弄坏了。我们的UV固化炉是低温固化,工作时不产生热风,避免空气扰动引入污染。设备还能加配百级净化进风系统,可以直接放在洁净车间里用。不管是注射器组装粘胶、导管接口固定,还是医用标签的瞬间贴合,都能在安全、洁净的环境下快速完成,特别省心。

| 设备尺寸 | 7200*3000*2500mm |

| 罐体直径 | Φ1000mm |

| 压力范围 | 0.1~0.8Mpa |

| 作业时间 | 可在参数页面设置,1~999min |

| 升温速度 | 室温至100°C,升温时间15min |

| 温度控制精度 | ±1℃ |

| 均温性 | 升温时士5℃℃,恒温时士3°C |

| 可存储配方数量 | 100组 |

| 温度设定范围 | 室温~100°C |

| 托盘尺寸 | 最大980*1180mm,采用双层托盘布局 |

| 数据上传 | 可配备手持式读码器,人工扫描产品ID,并上传至SFC/MES |

| 电源/功率 | AC380V/50HZ,20KW |