在线式精密无尘烤箱

一种用于提供高温净化环境的特殊在线式烘干设备;

多温区设计、加热仓百级无尘;

高效热风循环,精准控温水冷快速降温;

智能化控制、数据采集上传、可按需定制;

精密百级无尘烤箱|高端电子制造洁净热工艺解决方案

在摄像头模组AA制程、OLED面板PI固化与半导体先进封装等高端制造环节,传统工业烤箱已难以同时满足“百级洁净、±1 ℃级温度均匀性、>20 ℃/s 热变率”这一复合指标。世豪精密无尘烤箱经多轮迭代,它不仅是一个加热设备,更是一个可编程、可追溯、与智能产线无缝集成的在线式洁净热处理工作站。

产品优势

1. 洁净与温控:工艺可靠性的双重保障

百级无尘加热腔体:采用垂直层流(FFU)或循环风过滤设计,内部洁净度动态维持ISO 5(百级),静态可达ISO 4(十级),从源头杜绝热加工过程中的微粒污染。

多温区独立精密控制:加热腔沿传送方向分为多个独立温区,每个温区由独立PID模块控制,确保产品在移动过程中经历精准、稳定的预设温度曲线,消除传统单温区烤箱的“入口低温、出口高温”现象。

高效热风循环与快速水冷:特殊设计的风道与高性能离心风机,确保在百级洁净环境下仍能实现±1.0℃的温度均匀性。集成高效板式水冷换热器,可在完成高温工艺后实现>5℃/min的快速降温,大幅缩短生产节拍,提升产能。

2. 智能化与集成:生产管理的数据抓手

全自动在线式运行:集成自动上下料接口,实现与前后段设备的无缝衔接,满足连续生产需求。

全面的数据追溯:设备实时记录各温区温度、风机频率、压力、运行状态等所有参数,数据可通过SECS/GEM或OPC UA协议上传至工厂MES系统,为每一批次产品建立完整的“热工艺档案”。

配方与权限管理:海量配方存储,支持一键调用。多级操作权限管理,防止工艺参数被误改,确保生产一致性。

应用场景详解

1.摄像头模组自动对焦(AA)制程

工艺挑战:镜头与传感器主动对准后的UV胶固化,需要在高洁净环境中完成,以防止灰尘落在传感器或镜头上形成永久缺陷。同时,固化温度与均匀性直接影响对准精度保持。

解决方案:百级无尘环境,保障在胶水固化这一敞开环节的洁净度;多温区设计实现精准控温,确保胶水经历平缓、均匀的固化温度曲线,避免热应力导致微小的对准偏移;作为AA产线的一环,接受上位机指令,自动完成固化,实现全流程自动化。

2.OLED显示面板制造(PI固化、封装烘烤)

工艺挑战:聚酰亚胺(PI)浆料涂布后需要高温固化,其固化均匀性直接影响薄膜的应力与平整度,进而决定显示均匀性。封装胶的烘烤同样要求低污染和精准温控。

解决方案:卓越的腔体温度均匀性(±1.0℃),确保大尺寸基板(如G6代线)上每一点的PI固化条件一致;快速升温至固化温度,固化结束后快速冷却,满足高节拍生产需求,同时减少热历史对玻璃基板的影响;洁净环境防止烘烤过程中有机挥发物再凝结形成微颗粒,污染面板。

3.系统级封装(SiP)与芯片级封装

工艺挑战:底部填充胶(Underfill)、塑封料(Molding Compound)的固化工艺窗口窄,对温度极其敏感。温度不均或波动会导致固化程度不一,引发翘曲、空洞或界面分层等可靠性问题。

解决方案:多温区精密曲线,精确模拟并执行材料供应商推荐的“升温-保温-降温”全流程温度曲线;数据追溯性,完整记录每一托产品的实际固化温度曲线,为后续可靠性测试提供关键工艺数据,实现工艺与质量联动分析。设备长期运行的稳定性,是保证大批量生产封装体质量一致性的基础。

服务流程

我们理解采购新设备是一项重大投资。为此,我们提供透明的合作路径:

工艺可行性验证:欢迎寄送样品至我司净化热工艺实验室,进行免费初步烘烤测试,验证设备能力。【获取方案】

定制方案与详细报价:基于您的产能(UPH)、产品尺寸、工艺配方,提供详细的设备配置方案与报价。

工厂验收测试(FAT):设备出厂前,邀请您或您指定的第三方现场见证关键性能(洁净度、温均性、升温速率等)测试,确保符合协议要求。

现场安装与工艺调试(SAT):工程师上门安装,并使用您的实际材料进行工艺调试,直至达到量产要求。

长期支持:提供操作与维护培训,建立设备档案,提供备件支持与预防性维护计划。

| 设备尺寸 | 7200*3000*2500mm |

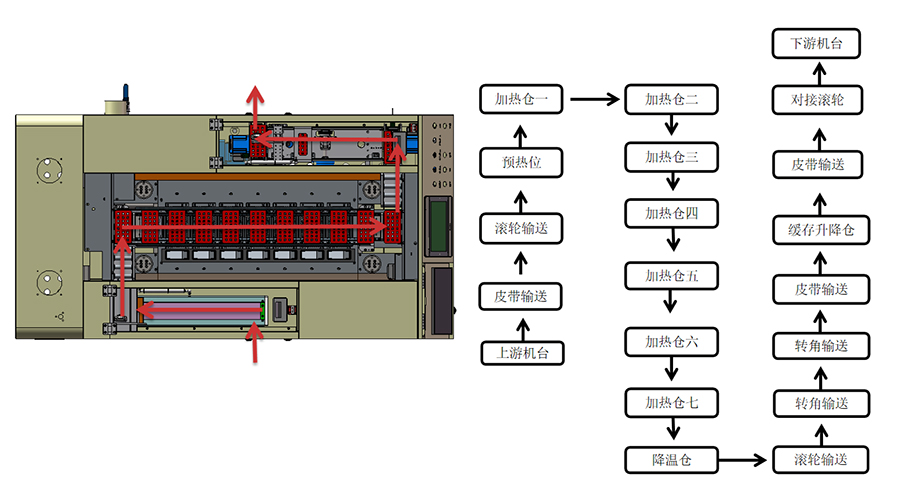

加热仓数量 | 7个加热仓,1个预热仓,1个冷却仓 |

进出板CT | 6s/pcs |

| 烘烤时间 | 可在参数页面设置,1~999min |

| 升/降温速度 | 室温至200°℃,升温时间20min水冷降温,200°C至50C,降温时间5min |

| 温度控制精度 | ±1℃ |

| 均温性 | 升温时士5℃℃,恒温时士3°C |

| 可存储配方数量 | 100组 |

| 极限耐热温度 | 250°C |

| 隔热性能 | 内腔温度200°C时,外壳50℃C以内 |

| 数据上传 | 自动扫码并上传参数至SFC/MES |

| 电源/功率 | AC380V/50HZ,30-45KW |