智能钢网库

钢网清洗后自动风干;

钢网自动检查,检查钢网清洗效果

钢网存储,资料保存,自动管理领用资料,上传至MES系统;

专用领料出口防止领料错误;

智能钢网存储与检测系统:自动化SMT钢网管理

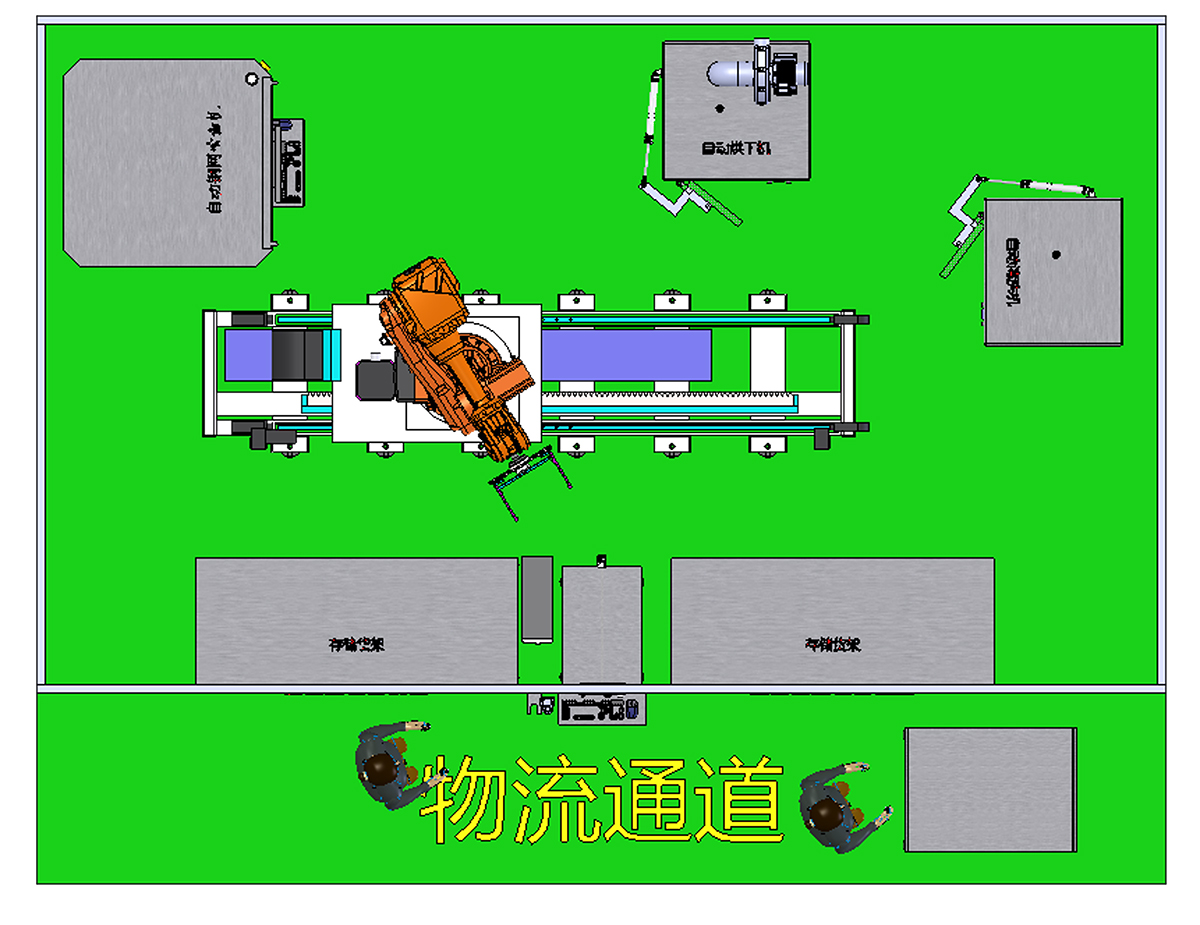

智能钢网存储与检测系统为SMT钢网管理带来革命性变革,将传统手动操作且易出错的流程转变为全自动闭环工作流。该集成系统将大容量存储、自动化处理与精密检测功能融合于单一智能单元。

该系统可自动管理钢网全生命周期——从存储调取、清洁(兼容现有自动钢网清洗机)到高精度检测。通过与MES/FX系统在线对接,实现实时追踪、消除人工记录误差,并提供深度数据洞察以持续优化工艺流程,确保即使是最棘手的03015和01005微型元件也能实现完美印刷。

产品优势

高容量自动化存储与检索

该系统彻底消除人工模板操作。凭借超过80块模板的存储容量及每小时12块以上的检索/归还速度(UPH>12),确保生产线始终能获取所需模板。系统定位精度达±0.05mm,确保与清洗及印刷工序实现精准交接。

SPC精密钢网检测

集成高分辨率视觉系统,突破单纯存储功能。具备检测03015及01005超细间距元件钢网垫片状态的关键能力。每次检测均生成完整数据并保存以实现全程追溯。核心功能包括:

缺陷照片归档:保存不良位置图像,便于随时调取复核

SPC统计分析:监控工艺趋势,预先识别潜在印刷问题

无缝MES集成与可追溯性

系统处于在线运行状态,可直接与工厂的MES(或FX)系统对接。每块钢网均通过其二维码进行管理,在每个工艺步骤扫描二维码即可自动更新状态并记录所有检测数据。这为库存中的每块钢网创建完整的数字孪生体与历史记录。

灵活操作与旧设备集成

本系统注重实用性,支持生产与调试双模式运行。其核心成本优势在于可与现有自动钢网清洗机无缝集成,既保护既有投资,又能全面提升自动化水平。

| 定位精度 | ±0.05 mm |

| 相机寿命 | ≥15000H |

| UPH | >12pcs/h |

| 仓储 | ≥300pcs |

PAD检查能力 | 具备03015,01005.尺寸钢网PAD检查能力 |

保存和追溯 | 设备检测的所有资料能被保存和追溯 |

| 产能 | 满足20M的钢网清洗、仓储需求 |

| 系统尺寸 | 6500*3900*2500 |